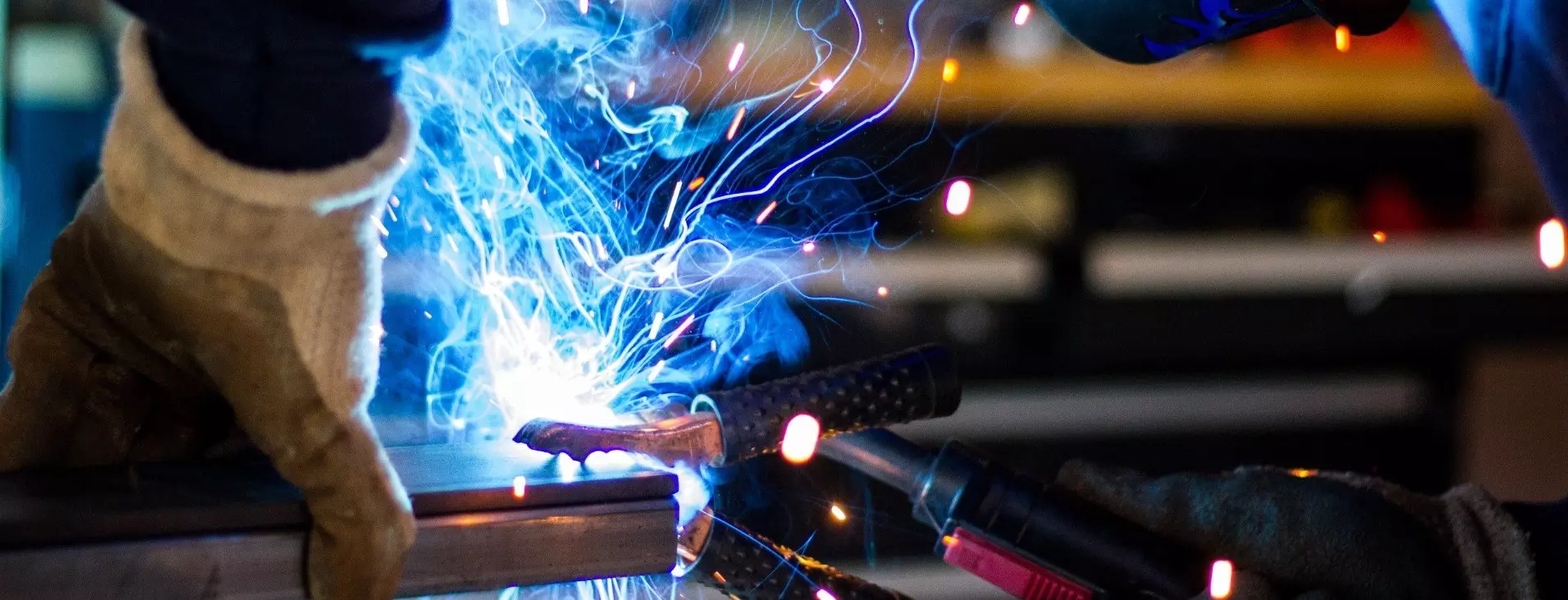

Are you looking for experienced Welding Services in Kent? We provide Metalwork Repairs, Vehicle Welding and industrial welding throughout Margate and Kent.

Mobile Welding Services

We provide a mobile service which offers a range of on-site metal fabrication and repairs. Our engineers work safely and efficiently to ensure all work is done to the highest standards possible for the job. Some of the services we provide with mobile welding fabrication include:

- Metal Fabrication

- Metal Repairs

- Acetylene Cutting

- Security Grill Installation

- Architectural Welding

- Walkway Repairs and Fabrication

- Gantry Repairs and Fabrication

Metalwork Repairs

Having metal that needs repairs can sometimes take up time. Therefore, we offer great services to repair all types of metalworks and get them looking great again and safe for use as soon as possible.

Vehicle Welding

Are you looking for a vehicle welding and repair service in and around Kent? We offer vehicle welding services to get you back on the road safe and sound as soon as possible while giving you quality service.

Industries we offer welding services for:

Aerospace

Welding is probably one of the best methods of fusing metals, and the aerospace industries have a range of uses for this.

Although gas welding was once a standard production method and still is used for some aircraft repairs while using TIG welding, they have been replaced by the electrical arc and plasma arc welding while using MIG welding for the manufacturing.

MIG welding is commonly used to manufacture aircraft, and plasma and electric arc welding are used for joining metals with precision work.

Automotive

An average vehicle requires thousands of welds to keep the metals together and safe for use.

Many automotive industries use MIG welding to create a strong bond between thin metals such as aluminium on the manufacturing line.

Automatic laser MIG welding is becoming more and more common as many understand its cost-effectiveness.

Manufacturing

MIG welding is used in many manufacturing industries, from computer components to machinery. This is due to its cost-effectiveness and speed at high-output manufacturing.

Due to the MIG welding's flexibility for working with many types of metals, it is used for a wide range of projects.

Railroads

Welding is essential for railroads as they ensure the steel does not separate and cause a train to derail.

A different type of welding was used when railroads were first used, and this was called spot welding, but this has changed over the years, making it more effective and stronger at bonding the metals together.

Shipping

Although many ships still have rivets installed to keep the different metals together for the boat, welding has become more popular with its speed and efficiency.

Also, welding has become a routine process when repairing damages on ships at a fast and efficient rate.

Frequently Asked Questions

About Welding Services in Margate and Kent

Find out more about our welding services in Kent from our frequently asked questions. If you require any further information, feel free to get in contact on 07583 864 751.

Maintaining and cleaning your roller shutters is essential to ensure they function smoothly and remain in good condition. Start by regularly removing dust, dirt, and debris from the shutters using a soft brush or vacuum cleaner.

For cleaning, use a mild detergent mixed with warm water and a soft cloth to wipe down the surface of the shutters.

Avoid abrasive cleaners or harsh chemicals that could damage the material or the paint finish. Rinse with clean water and dry with a soft towel to prevent water spots.

Additionally, it’s important to check the mechanisms, such as the tracks and hinges, for signs of wear or obstruction.

Lubricating the moving parts, like the guides and bearings, with a silicone-based spray will keep everything running smoothly. Scheduling a professional inspection annually can help identify potential issues before they become serious problems.

Yes, roller shutters can indeed be automated or motorised, providing a high level of convenience and ease of use. We offer motorisation for both new installations and existing manual shutters.

Motorised roller shutters can be operated using a wall switch, remote control, or even through smart home systems that allow you to control the shutters via a mobile app. This is particularly beneficial for larger or hard-to-reach shutters, making operation simpler and more efficient.

Furthermore, our motorised systems come with safety features such as auto-reverse mechanisms that prevent the shutters from closing if an obstruction is detected. This feature not only enhances ease of use but also improves the overall safety of the system.

Yes, our roller shutters are highly versatile and suitable for both residential and commercial properties. For residential applications, we provide shutters that offer enhanced security, privacy, and insulation, ideal for garages, windows, and home entrances.

These shutters are available in a variety of colours and finishes to complement your home’s exterior while providing practical benefits.

In commercial settings, our heavy-duty roller shutters are perfect for securing shopfronts, warehouses, and industrial units. They are designed to withstand harsh environments and deter potential intruders while still offering easy operation and durability.

We understand that every property has unique needs, so our team can customise roller shutters to match your specific requirements, ensuring functionality and aesthetic appeal for any application.

Yes, we provide comprehensive repair services for damaged roller shutters. Our experienced technicians are equipped to handle a wide range of issues, including broken or bent slats, malfunctioning motors, misaligned tracks, and general wear and tear.

We understand how important it is to have functional and secure roller shutters, so we strive to offer prompt and effective repair solutions.

Whether it’s an emergency situation or a routine maintenance requirement, our team will diagnose the problem and carry out the necessary repairs to restore your shutters to optimal condition.

Additionally, we offer preventative maintenance services to extend the lifespan of your shutters and minimise future issues.

While welding is a versatile process that allows various metals to be joined, there are certain metal combinations that cannot be successfully welded together. One common issue arises when trying to weld metals with significantly different melting points.

For example, aluminium and stainless steel are not typically welded together using conventional welding methods, as their melting points and thermal conductivities differ greatly.

Similarly, titanium and steel are generally incompatible for welding due to their differing chemical and mechanical properties. Metals that form brittle intermetallic compounds, such as copper and aluminium, also present challenges.

Even when a weld seems possible, the resulting joint may lack the strength or durability needed for practical applications. In such cases, special techniques like explosion welding or the use of transitional alloys may be required. It's important to consult a professional welder to determine the best approach for your specific project.

For your free, no-obligation quote

If you require welding services in Margate, Kent or the surrounding areas get in touch today.

Contact Us

Unit 3, Copperleaf Business Park, Dane Valley Road, Broadstairs Kent, CT10 3AT 07583 864 751 | s.fab1@yahoo.com

Find us on Flickr!