Discover the advantages of Acetylene Cutting. Our portable, easy-to-use services deliver precise cuts, making it a perfect solution for various industries in the UK.

Portability and Ease of Use

Acetylene cutting is widely used in industrial and construction settings due to its portability and ease of operation. The system consists of gas cylinders, a cutting torch, hoses, and regulators, all of which can be transported easily to different locations. This makes it ideal for on-site cutting tasks, especially in areas where stationary cutting machines cannot be used.

Unlike plasma or laser cutting, which depend on electricity, acetylene cutting relies solely on gas combustion. This allows operators to work in remote locations, construction sites, and outdoor environments without needing access to electricity. The cutting process itself is relatively simple, as only the correct gas mixture and proper flame adjustment are needed. Operators can quickly ignite the torch, preheat the metal, and introduce the oxygen stream to initiate the cutting.

While safety precautions are necessary since acetylene is flammable, the system remains an accessible and efficient method for cutting metal in diverse environments. Its portability and ease of use make it a preferred choice for many industries.

Precision and Clean Cutting Edges

Acetylene cutting is a reliable method for producing precise and clean-cut edges in metal fabrication. The process involves generating an intense flame and using oxidisation to remove slag and create smooth, accurate cuts.

With acetylene cutting, operators can adjust the gas ratio for different metal thicknesses, and ensure that there's a clean and efficient cut every time. Attachments and cutting guides can also be used to create straight or curved cuts.

Compared to mechanical cutting methods, acetylene cutting produces minimal burrs and requires little post-processing, and any remaining slag can be easily removed with a chipping hammer or a grinder. This makes the process ideal for structural steelwork, metal components, and repair tasks.

Effective for Scrap Metal Recycling and Demolition Work

Acetylene cutting is a highly effective method for scrap metal recycling and demolition since it can cut through thick metal quickly and efficiently. The process involves using an oxy-acetylene torch to generate a high-temperature flame, which preheats the metal before using pure oxygen to oxidise the metal. This allows large and heavy metal structures to be broken down into manageable sections for recycling or disposal.

Unlike mechanical cutting methods, which can be slow and require specialised equipment, acetylene cutting allows workers to cut irregularly shaped or heavily rusted materials with ease. This makes it an essential tool in scrapyards and metal recycling facilities.

For demolition work, acetylene cutting can cut through thick steel girders, machinery, and reinforced frameworks quickly. This helps reduce the time and labour that's often needed for demolition projects. Additionally, since acetylene-cutting equipment is portable, it can be used in remote locations or sites where electricity is unavailable.

Versatility in Metal Thickness and Types

Acetylene cutting can cut various metals and materials of different thickness levels. The oxy-acetylene process generates an intense flame of around 3,500°C, allowing it to cut through a wide range of metals.

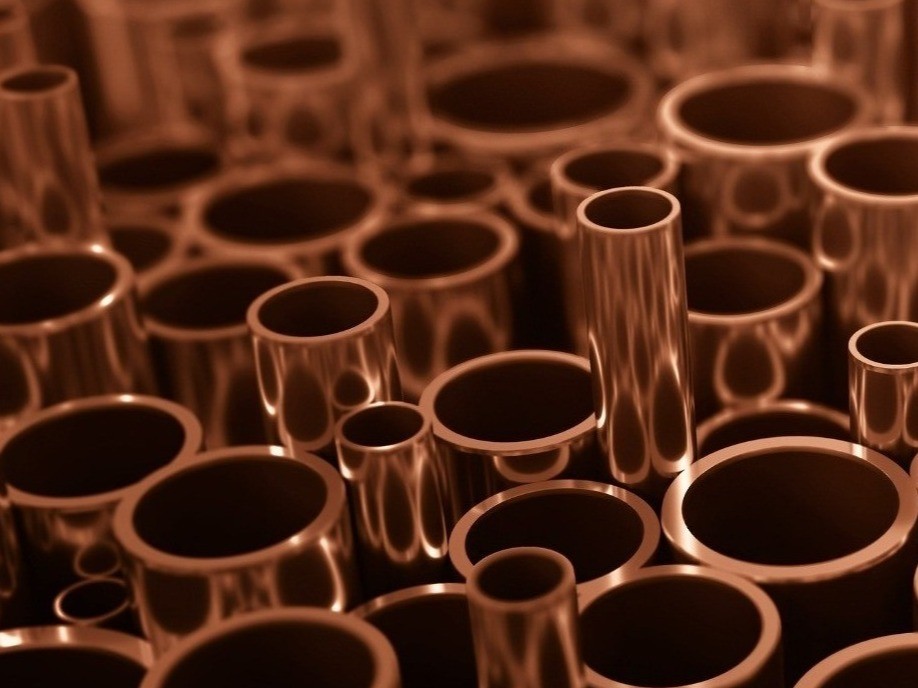

Acetylene cutting can cut through thick metal with ease. It's commonly used for cutting steel plates, beams, and pipes, making it ideal for heavy-duty industrial applications such as construction, shipbuilding, and metal fabrication. The flame and oxygen flow can be adjusted to accommodate different thickness levels and ensure a precise cut consistently.

Although acetylene cutting is ideal for ferrous metals like mild steel and carbon steel, it can also be used on other materials. This cutting method can also be used to create straight cuts, bevel cuts, and shape cutting with the right attachments. This makes it a valuable tool for industries that need custom metal-cutting solutions.

Overall, acetylene cutting is a flexible and widely used method since it can handle different types of metals and thicknesses efficiently, making it a preferred choice for many industries.

Faraday Fabrications provides professional acetylene-cutting services across the UK. We can cut through thick steel and ferrous metals efficiently and deliver clean, accurate cuts for a range of applications.